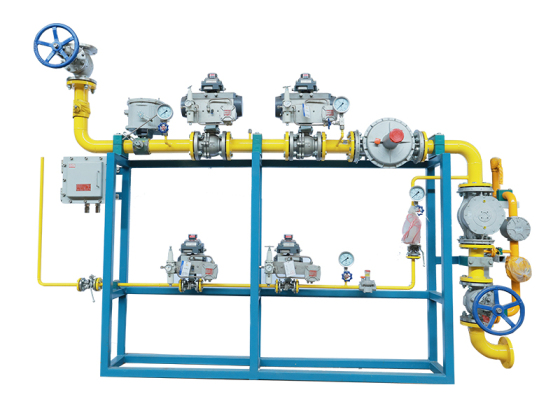

skid mounted LNG module

1. Enhanced mobility: Piled systems facilitate easy relocation via skid and modern machinery.

2. Modular design: Load-out skids integrate diverse components onto a single, sturdy steel frame.

3. Streamlined interface: Minimal connections, focusing on process access, power, and communication.

4. Future-proof setup: Compact, versatile solution optimizing industrial equipment deployment.

- SQ

- China

- 30days

- 300

- Information

Skid mounted LNG module description

Piling refers to a modular system where a collection of equipment is permanently mounted on a steel foundation, typically made of angle or I-beams, designed for easy relocation and positioning using lifting equipment. A load-out skid, in this context, is an integrated structure that combines the load-out control system, flow meters, valves, piping, ancillary equipment,flooded mast, intermediate connectors, as well as cables, bridge supports, all within a single cohesive steel platform. The assembled and interconnected part of this setup features only the necessary process connections for fluid handling, power supply for controls, and communication interfaces, leaving openings for these purposes.

A comparison between On-Road Load-Out Skids (Containerized Load-Out Skids) and Traditional Field Installation

| Traditional Site Installation | Containerized Load-Out Skid |

|---|---|

| Installation Process | Integrated Production |

| - Multiple on-site procedures, communication barriers between suppliers and installers<br>- Limited protection for expensive instruments<br>- Long lead times, lower quality | -Factory-integrated, no concurrent work - Ensures high-quality and stable system - Immediate after-production quality control |

| System Debugging | Factory Testing |

| - Uncertainties in instrument issues, cable connections, device fit<br>- Complex and extended on-site testing<br>- Risk of instability | - Comprehensive integration in factory - Eliminates installation errors - Factory-tested, guaranteed system stability - Standardized approach |

| Costs | Cost Efficiency |

- Material waste, increased costs due to lengthy process - Ongoing maintenance and debugging expenses post-installation | - Reduced material waste, shorter project timelines - Lower upfront installation costs - Minimized post-installation issues and maintenance expenses |

| Overall Benefits | Increased Reliability |

| - Lower efficiency, quality inconsistencies | - Higher efficiency, consistent performance - Predictable lifecycle and reduced downtime |

skid mounted LNG module Main function

1. Both gas and liquid input.

2. Tank-to-tank transportation.

3. Unloading.

4. Filling.

5. Exhausting air.

6. Multilayer filter.

7. Power leakage protection.

8. Wholly explosion-proof electrical equipments.

9. Gas leakage exceeding limits, the power being closed automatically.

10. Two-stages gas leakage alarm.

11. If the liquid level is too high or too low, there is alarm to tell you automatically.

12. If the liquid level is too high or too low, pumps would be closed automatically.

13. Emergency shutdown.

14. Spraying automatically.

15. Level indicator.

16. Temperature indicator.

17. Pressure indicator.

18. Metering indicator.