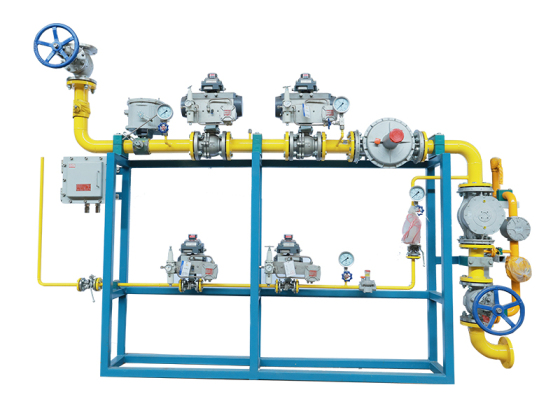

Gas pressure regulator

The liquefied natural gas (LNG) after being vaporized goes through pressure regulation, metering, odorization, and safety venting before being fed into the gas pipeline. The LNG skid-mounted system is divided into sections: unloading, vaporization skid, and pressure control skid.

- SQ

- Shanghai

- 90days

- 15

- Information

The liquefied natural gas (LNG) is first vaporized and then undergoes pressure regulation, metering, odorization, and safety venting before being input into the gas pipeline. The LNG skid-mounted setup typically comprises three main components:

Unloading Skid: This section is responsible for the safe off-loading of LNG from a transport vessel or truck into storage tanks or directly to the vaporization system.

Vaporization Skid (or Gasification Skid): After unloading, the LNG is vaporized into its gaseous state. This process converts the liquid LNG back into natural gas, which is then ready for distribution.

Regulation Skid (or Pressure Control Skid): Once the gas is in its gaseous form, it goes through a pressure regulation process. This ensures that the gas is at the appropriate pressure level required for distribution through the pipeline network. The regulation also helps maintain safe operational conditions within specified pressure bands.

This systematic approach ensures efficient and safe handling of LNG, transforming it from a liquefied state to a form suitable for transmission over long distances via pipelines.