- Home

- >

- Products

- >

- Gas regulating skid

- >

Gas regulating skid

. Compact design for space-saving;

. Supports remote monitoring to enhance management efficiency;

. Utilizes atmospheric heating for gasification, effectively reducing operational costs;

. Modular and integrated structure for easy installation and short construction schedules;

. Simple operation and maintenance, reducing labor costs;

. Highly portable, supporting repeated use at multiple locations.

- SQ

- Shanghai

- 30days

- 15

- Information

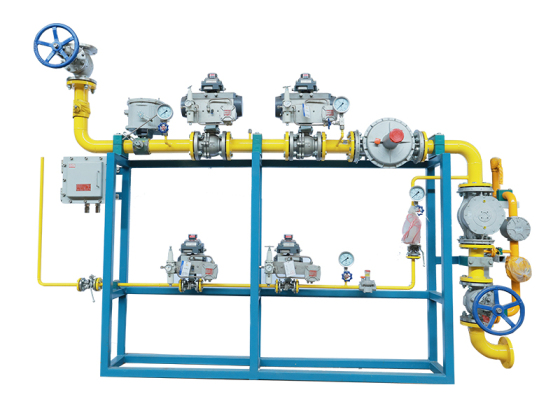

Description of Pressure Regulating Skid:

The skid-mounted gas supply terminal is developed for residential neighborhoods, small to medium-sized business users, and large public buildings based on their monthly gas consumption needs. It integrates all functional components except the LNG storage tank onto a skid, offering compact size with minimal footprint, short manufacturing periods, and convenient installation. The entire system is designed, manufactured, tested, debugged, and provided with after-sales service by professional manufacturers, ensuring reliability and ease of use. Installation work is minimal, involving only the connection of inlet and outlet pipelines and external electrical connections, making it easy to operate and maintain safely, with the capability for remote monitoring and operation from any location.

Gas regulating skid Features:

Comprehensive Functionality: Consolidates storage tank pressurization, gasification, pressure regulation, metering, odor addition, and electrical control functions into one unit.

Compact Design: Offers a compact layout and small area requirement.

Remote Monitoring: Supports remote monitoring for real-time control and operation.

Thermal Heating: Utilizes atmospheric heating for gasification, reducing operational costs.

Skid-mounted Assembly: Facilitates easy installation with a short construction cycle.

Ease of Operation and Maintenance: Requires simple operation and maintenance.

Portability: Equipped for mobility, allowing for reuse at multiple locations.

Safety Features:

Safety Valves: Features a low-pressure liquid phase safety valve, a gas phase safety valve, and a safety relief valve.

Emergency Shut-off Valve: Includes a liquid phase emergency shut-off valve.

High-pressure Emergency Shut-off Valve: Equipped with a high-pressure gas phase emergency shut-off valve.

Static Grounding: Ensures static electricity grounding with all cables routed to a flameproof junction box.

Heating System: Incorporates natural gas water bath heating to ensure operational efficiency at lower temperatures.

Monitoring System: All pressure, temperature, liquid level, current, and voltage signals are linked to the monitoring system to ensure the safety of the station area.