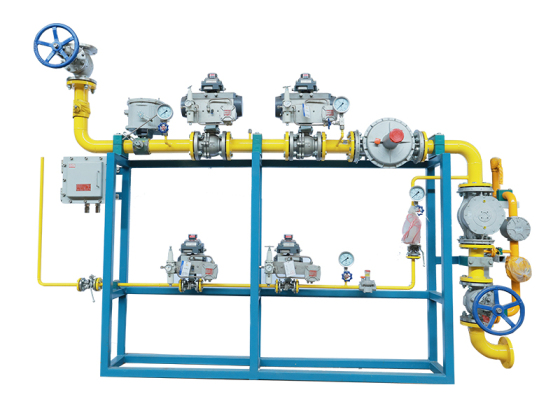

Gas pressure regulating skid

· The Gas Pressure Regulating Skid boasts precise control capabilities due to its advanced instrumentation, allowing for dynamic adjustments that maintain consistent output pressure under varying conditions.

· One of its key highlights is the integration of automated safety features, which monitor and adjust pressure in real-time, preventing overpressure and ensuring the integrity and longevity of the system.

· Additionally, the modular design of the skid enhances flexibility and ease of maintenance, enabling operators to quickly address issues and optimize performance with minimal downtime.

- SQ

- Shanghai

- 90days

- 15

- Information

Process Flow Description

Unloading Process:

LNG Tanker - Transport LNG from an LNG liquefaction plant to the car refueling station using a low-temperature transport tanker.

Sealed Coupling - Connect to the dedicated refueling interface on the tanker, ensuring airtightness during the process.

LNG Pump - Use vacuum pipes and submersion pumps to transfer LNG from the tanker to the LNG storage tank.

LNG Storage Tank - Collect and store the unloaded LNG for subsequent car refueling.

Function Realization:

Utilize a standard booster to unload LNG, sharing a booster with the storage tank to implement a regular LNG vaporization unloading method. This can be used for initial unloading or to protect the pump by reducing its usage frequency as an emergency solution, without considering costs.

Car Refueling Process:

LNG Storage Tank - Obtain LNG from the refueling station's LNG storage tank.

LNG Pump - Pressurize the LNG through the submersion pump for refueling purposes.

Flow Meter - Measure the volume of LNG being transferred to ensure precise refueling.

Car's LNG Bottle - Connect the outlet pipe to the car's LNG bottle filling port and use the refueling panel to control the pump's operation and delivery flow. Simultaneously, use the LNG flow meter to track the delivered liquid, displaying (or billing in cubic meters) and pricing on the control panel.

Venting Process:

LNG Storage Tank - Monitor the gas phase pressure inside the tank.

Safety Valve - Automatically vent when the tank's pressure exceeds the set limit, ensuring safety.

Manual Operation - Open the vent valve manually to further relieve pressure if necessary.

Note:

This process flow describes the safe and efficient operational procedures for transporting LNG from a liquefaction plant to a refueling station and then refueling vehicles.

Each step is designed with considerations for energy recovery and environmental protection, ensuring sustainability and safety throughout the process.

Specific operations should comply with relevant industry standards and safety regulations to ensure the safety of all personnel and equipment involved.