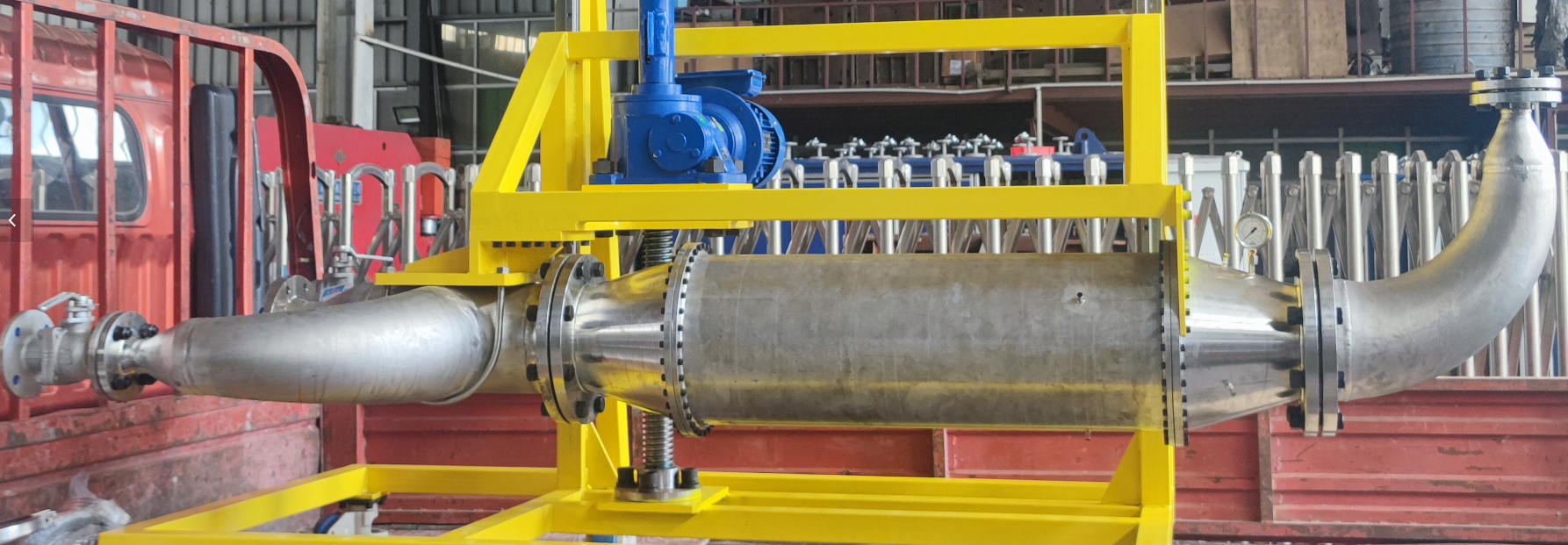

Steam pressure and temperature reducing skid

The modular design of Steam pressure and temperature reducing skid makes it easy to install, configure, and maintain, minimizing downtime and operational costs. This feature, combined with its energy-efficient design and compact footprint, contributes to reduced environmental impact and optimized performance for steam system management.

- SQ

- shanghai

- 30days

- 20

- Information

General

Introducing our innovative Steam Pressure and Temperature Reducing Skid, a cutting-edge solution designed to optimize steam management in industrial processes. This skid seamlessly integrates steam pressure and temperature control functionalities, offering unparalleled efficiency and reliability for various applications.

Features

The Steam Pressure Reducing Skid is a pivotal component of our offering, engineered to precisely regulate steam pressure according to specific process requirements. It ensures consistent steam supply, preventing over-pressurization and minimizing energy waste. By maintaining optimal pressure levels, it enhances system performance and prolongs equipment lifespan.

Complementing this feature is the Temperature Reducing Skid, which effectively manages steam temperature, preventing overheating and ensuring process stability. This skid's intelligent design allows for fine-tuned temperature adjustments, safeguarding sensitive materials and processes from thermal stress.

Together, the Steam Pressure and Temperature Reducing Skid forms a comprehensive steam management system, embodied in a robust and compact skid-mounted unit. The steam skid's modular construction facilitates easy installation, maintenance, and portability, making it an ideal choice for both new installations and retrofitting projects.

In summary, our Steam Pressure and Temperature Reducing Skid is a game-changer in steam management, delivering precise control over steam pressure and temperature. Its efficient design, combined with the convenience of a skid-mounted solution, sets a new standard for industrial steam systems, promising enhanced process efficiency, reduced energy consumption, and extended equipment longevity.