Steam pressure reducing skid

1. Versatile pressure control: Tailored for industries needing precise steam management, ensuring high-quality products and efficient processes.

2. Wide applicability: Suitable for diverse sectors like food and chemicals, maintaining consistent steam supply vital.

3. Energy-saving feature: Prevents over-pressurization, contributing to minimized energy wastage and cost savings.

4. Modularity and adaptability: Designed for quick integration in new builds and existing sites with ease of installation.

- SQ

- shanghai

- 30days

- 20

- Information

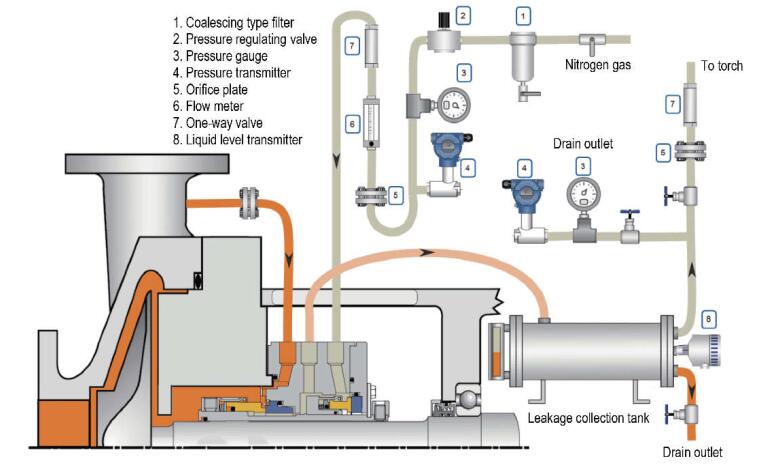

As a specialist manufacturer in industrial steam solutions, we are proud to offer our Steam Pressure Reducing Skid. This innovative skid is designed to optimize steam management, providing precise control over steam pressure and temperature for enhanced process efficiency.

The Steam Pressure Reducing Skid, also known as a pressure reducing skid, is a compact and efficient solution for managing steam pressure in industrial applications. Its intelligent design ensures consistent steam supply, preventing over-pressurization and minimizing energy waste. By maintaining optimal pressure levels, it enhances system performance and prolongs equipment lifespan.

In addition to its pressure reducing capabilities, this steam skid also incorporates steam temperature reducing functionality. This allows for effective management of steam temperature, preventing overheating and ensuring process stability. The skid's intelligent design enables fine-tuned adjustments, safeguarding sensitive materials and processes from thermal stress.

Constructed with high-quality materials, the Steam Pressure Reducing Skid is built to withstand demanding industrial environments. Its modular design facilitates easy installation, maintenance, and portability, making it an ideal choice for both new installations and retrofitting projects.

Choose our Steam Pressure Reducing Skid for unparalleled steam management capabilities. Experience the difference it can make in optimizing your industrial processes, enhancing efficiency, and ensuring precise control over steam pressure and temperature.